Comparison Between Lacquer Cutting and DMM

Two Processes, One Decisive Choice for the Quality of Your Vinyl: Lacquer Cutting or DMM?

In the demanding world of vinyl record production, the cutting process is a crucial step that shapes the final sound quality. Lacquer cutting or DMM: each method has its own unique characteristics and advantages. But which one will best elevate your vision and perfectly meet your expectations? Explore the differences and make the choice that truly makes a difference.

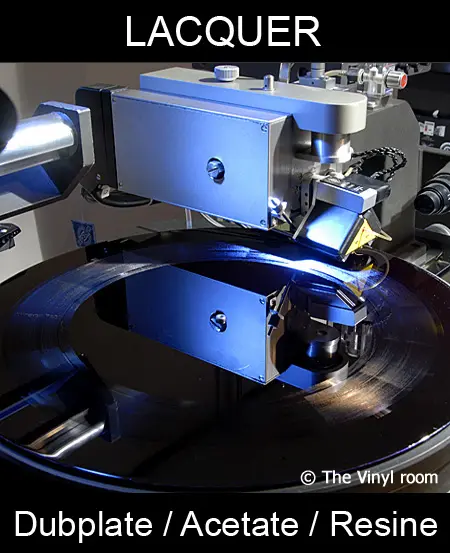

Lacquer Cutting

Lacquers, made from resin (also known as Acetate or Dubplate), offer unique characteristics that make them a benchmark for sound quality. The resin composition allows the cutting head to achieve greater groove depth, resulting in richer, warmer sound and exceptional dynamics. This ability to capture a wide frequency range and faithfully reproduce the nuances of a recording makes lacquer cutting a preferred choice for high-end and audiophile productions.

However, this superior sound quality comes with technical challenges. The galvanization process associated with lacquers is longer and more complex compared to DMM. This is due to the fragility of the resin, which requires meticulous handling to avoid defects, as well as additional processing steps necessary to ensure optimal galvanization. These requirements inevitably increase production costs in terms of both time and resources.

Choosing lacquer cutting thus involves a greater investment, but it is well worth it for projects where sound quality takes precedence over cost and time constraints. This method is ideal for productions aiming for excellence, such as limited editions, audiophile artist recordings, or masters intended for a discerning audience. In short, while more expensive, lacquer cutting remains an essential option when producing vinyl records that push the boundaries of fidelity and the listening experience.

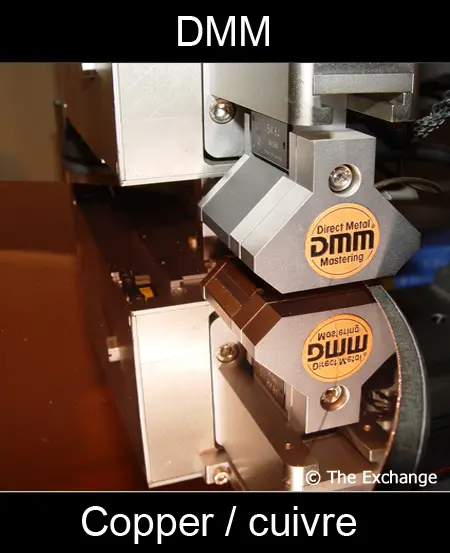

DMM (Direct Metal Mastering)

Direct Metal Mastering (DMM) is a direct cutting technology that offers the advantage of being the fastest option in the galvanic process, making it the most cost-effective production method. This efficiency and economic advantage stem from the absence of intermediate steps required in traditional galvanization, such as those necessary for lacquer cutting.

However, this method has a significant limitation tied to the nature of the material used. Unlike lacquer cutting, which uses a resin base (Acetate or Dubplate), DMM involves engraving directly onto copper, a metal. This difference in material affects the final sound quality, particularly in terms of output levels. With equivalent cutting, DMM results in an approximate 2 dB loss compared to lacquer.

This disparity arises from the acoustic properties of copper. While copper provides excellent precision in reproducing high frequencies and offers remarkable stability, it cannot achieve the same depth and warmth in sound as lacquer. Additionally, lacquer cutting remains the benchmark for recordings where optimal sound quality is a priority, thanks to its ability to reproduce wider dynamics and richer harmonic detail.

CONCLUSION

At BLM Studio, quality is our top priority. This is why we have chosen to work exclusively with MDC lacquers, renowned for their excellence and imported directly from Japan. This decision ensures our clients receive an exceptional sound experience, perfectly aligned with their most demanding expectations.