All you need to know about Lacquer Cutting and LP Records

The vinyl record is an emblematic music-listening medium, renowned for its round shape and characteristic black color. But did you know that each vinyl record is the result of a meticulous manufacturing process, including the engraving of lacquers?

lacquer Cutting: the art of creating vinyl LPs

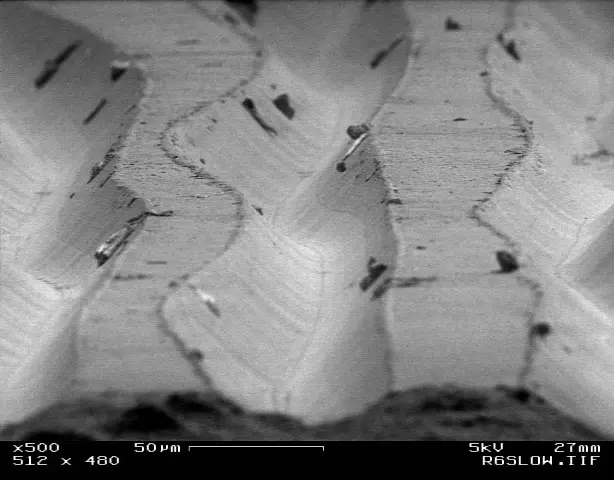

Each side of a vinyl record is engraved with a microgroove, a microscopic groove that translates the sound recording into analog vibrations. This surgically precise groove is engraved on a lacquer specially designed for this crucial step. This delicate process requires advanced technical know-how and state-of-the-art equipment to guarantee optimal, faithful sound reproduction.

The engraving of vinyl lacquers is the starting point for the manufacture of each vinyl record. It determines the finesse and depth of sonic detail, offering listeners a rich, authentic musical experience. But how exactly does the LP work, and why is it so important in vinyl production?

Explore our expertise in professional lacquer etching and discover the secrets of this artisanal and technological know-how, essential to the production of high-quality vinyl records.

Microsillon: a precise art for innovative vinyl records

The spiral-engraved groove follows strict standards in terms of width and shape to ensure smooth playback of the recording. This groove always begins on the outside of the record and ends on the inside. Although vinyl is traditionally round and black, it can also take on a variety of shapes and colors, adding an aesthetic and personalized dimension.

However, it is possible to push back the traditional limits of microgroove engraving . Some creative techniques, for example, allow two parallel and intertwined microgrooves to be engraved. This innovation offers a unique experience: the turntable diamond alternates randomly between the two grooves, modifying the sound playback.

Another notable technique is to engrave an endless groove at the end of the disc. Instead of a silent space designed to prevent the diamond from reaching the central label, this microgroove can contain a musical phrase played in an infinite loop. Many artists have exploited these possibilities to enrich their works and surprise listeners.

Discover how innovations in microgroove engraving combine creativity and sound quality, making the vinyl record much more than a simple listening medium.

The evolution of the microgroove in vinyl records

The standard of the single-microgroove, twelve-inch 33 rpm vinyl record established itself as a benchmark over the course of the 20th century, consolidating its dominant position at the beginning of the 21st century. However, the possibilities offered by the exploitation of the microgroove far exceed this traditional format, paving the way for fascinating technical innovations.

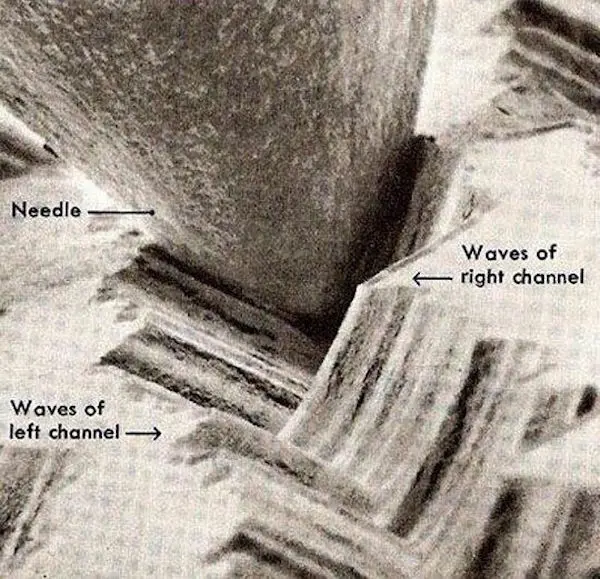

These advances included innovative formats, although they were not massively commercialized. For example, double microgrooves , one for each channel, have been developed. With two simultaneous playback heads, this concept enables sound reproduction that's close to binaural , offering unprecedented acoustic immersion.

Other experiments attempted to push the limits of the microgroove, seeking to store quadraphonic recordings on it. Despite these efforts, these discs were confronted with technical constraints, notably crosstalk problems in the midrange, limiting their adoption.

These innovations testify to the infinite potential of LP recording, combining traditional craftsmanship with cutting-edge sound engineering. The vinyl record thus continues to evolve, offering promising prospects for analog music enthusiasts and demanding audiophiles alike.

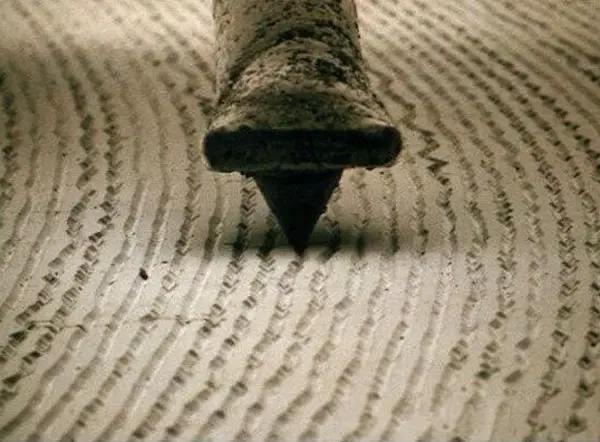

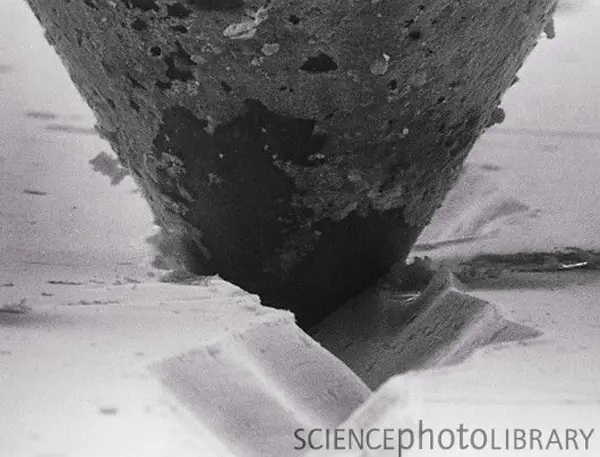

Optical microscope view of the groove

We can see the oscillation of the groove

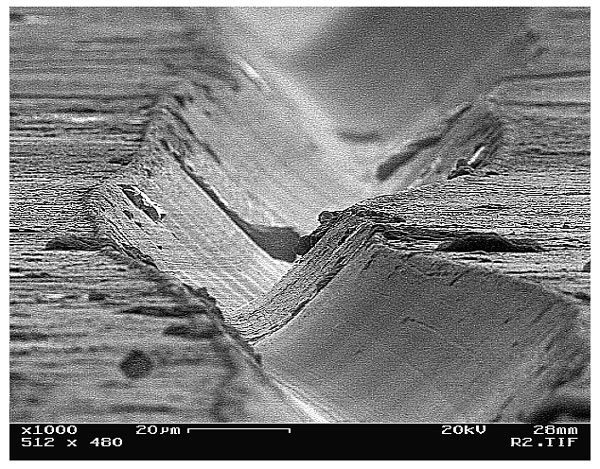

Engraving head

The diamond of the SX 74 etching head is magnified.

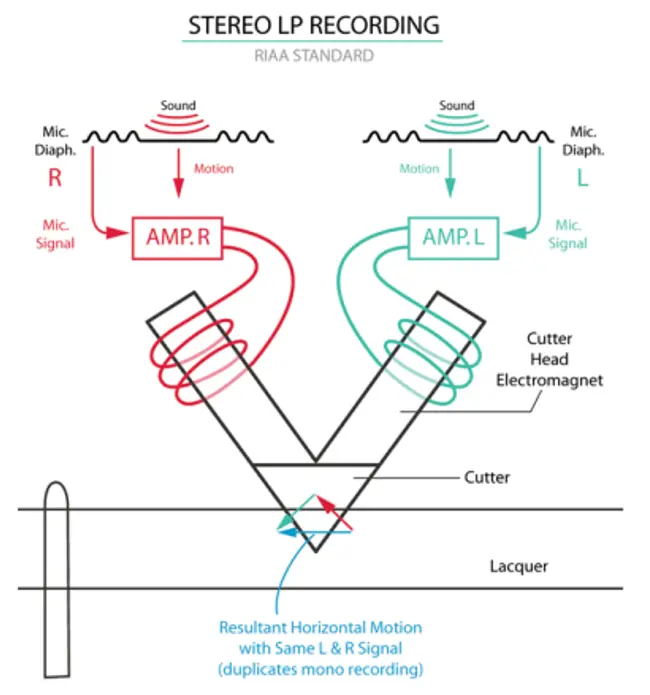

Stereo view

We can see the output shape of the 2 output channels

Neumann VMS80: An iconic machine for burning vinyl records

The studio is based on a Neumann VMS80 cutting tower , an iconic piece of equipment fully restored and in service since its launch in the early 1980s. This equipment tests to the exceptional longevity and unrivaled quality of Neumann equipment , recognized worldwide in the vinyl record industry.

Neumann's history in the production of cutting lathes dates back to 1929, with the launch of the AM29, just one year after the company was founded. Building on decades of innovation, in 1970 Neumann introduced the VMS70 model, a machine already incorporating significant technical advances derived from its experience. In the 1980s, the VMS70 was replaced by the VMS80 and VMS82 models, the last representatives of this expertise before the company ceased production of engraving towers in 1993, due to the growing dominance of the CD.

The Neumann VMS80 remains a true classic and the best recording machine on the market today. It embodies the golden age of vinyl , offering unrivaled precision and sound quality. It's an invaluable piece of equipment for all vinyl professionals and enthusiasts, a symbol of craftsmanship and technological know-how unique in the history of engraving.